Our Manufacturing Process: from Yarn to Y.O.U underwear!

Want to find out how our organic underwear is made?

It's more complicated than you might think!

We went to India last year to visit our manufacturer and to meet the team. It was amazing to find out about the hidden stages behind the underwear we love, so we thought we'd share them with you here! If you prefer to watch rather than read, check out our video!

There are nine stages in the manufacture of Y.O.U underwear

The first step in our manufacturing process is knitting. This is where reels of organic cotton are turned into the fabric that will soon become our underwear. Huge circular machines take the cotton threads from the reels and use a series of needles to turn them into fabric.

This new fabric then needs to be quality checked. It’s unrolled over a giant light box to allow the team to check for imperfections.

To achieve that perfect underwear shade, the fabric is then dyed. All the dyes used by our manufacturer are low impact, fibre reactive and GOTS certified, meaning that they’re much better for workers, the planet and ultimately our customers.

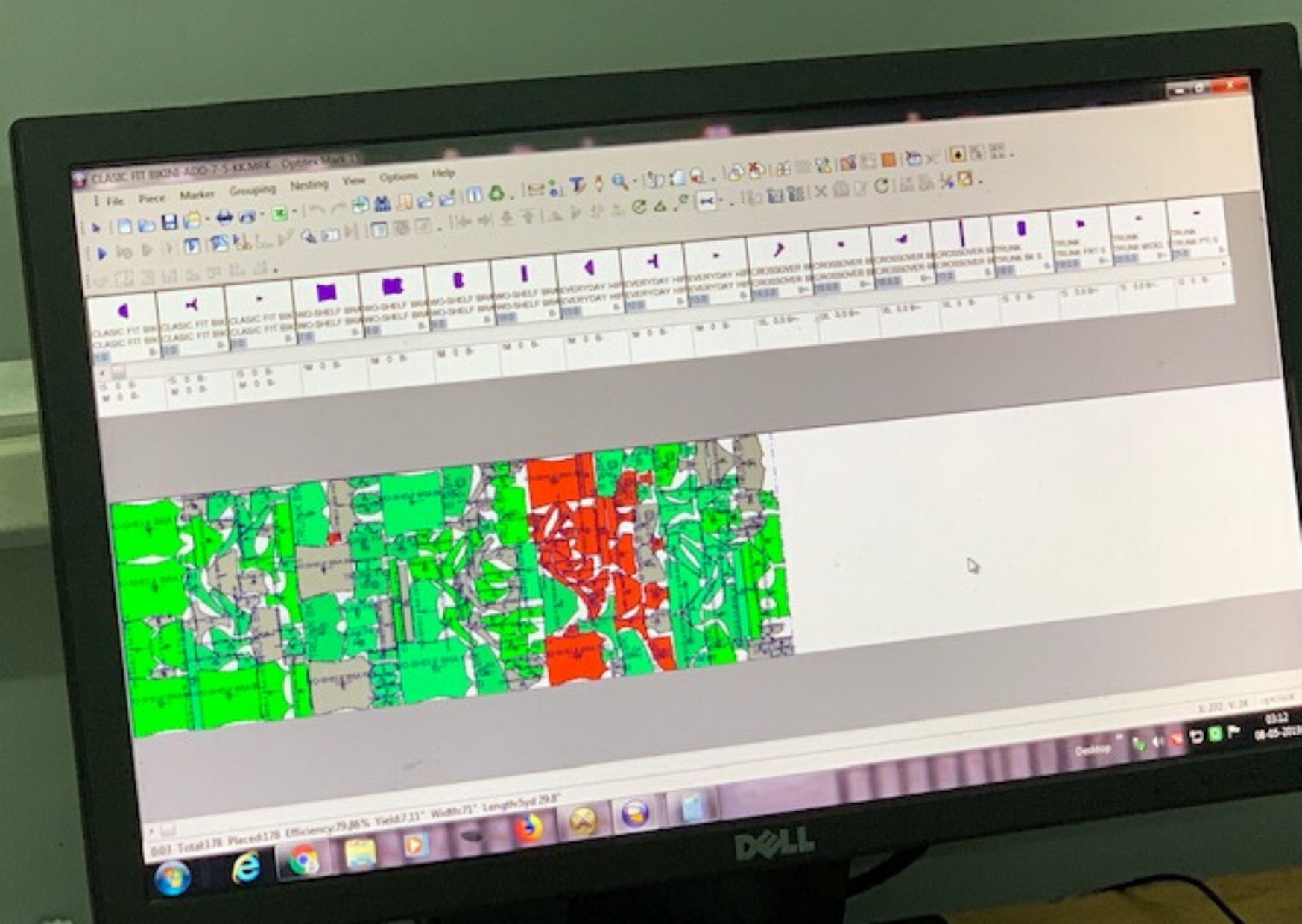

Good design is the basis of any loved garment, and this is where our unique patterns come in. After being photographed and digitised, special software is used to fit our patterns onto the fabric efficiently in order to minimise fabric wastage. Once they’re digitally arranged, they can be easily printed and laid on top of the fabric.

Cutting! These blocks of fabric are 100 layers thick! The patterns are arranged on top, and an operator uses a machine to cut around the shapes. The block of fabric is 100 layers thick! Any offcuts are carefully collected and sent to be recycled.

All these separate pieces are then stitched together…and our underwear begins to take shape. Individual garment workers sew seams together, along with other elements like elastic. It’s a bit like completing a puzzle.

Next comes the finishing, where any hooks, catches, and fastenings are added. The finished products are also quality checked for size and imperfections such as loose threads and seams.

Our finished undies are then packed according to style and size. A minimal amount of plastic is used, just enough to protect the underwear from moisture on their journey.

...And finally, our undies are ready to be dispatched to the UK!

If you’ve got any unanswered questions about our manufacturing process, leave a comment. We’d love to hear from you!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.