The journey of Y.O.U Underwear

At Y.O.U Underwear, we work with two of India’s leading sustainable and ethical manufacturers. We work with Connoisseur Fashions in Chennai and Tiruppur in Tamil Nadu and Rajlakshmi Cotton Mills in Kolkata. Both our manufacturers operate under SA8000 certified social standards.

Connoisseur Fashions is passionate about their responsibility to help make their local community a better place to live and work. We chose to partner with them because of their strong ethical credentials, their values, and their focus on empowering women in particular.

Knitting

Printing & Dyeing

Cutting & Sewing

Finishing Touches

Made with Organic Cotton

Our manufacturers use only GOTS certified organic and Fairtrade cotton. Organic cotton is better for the environment by using 91% less water and 62% less energy than traditional cotton. It uses less harmful chemical and pesticides making it safer for the envrionment and workers. Fairtrade cotton means workers are paid the Fairtrade premium. Our manufacturers use cotton from Chetna Organic- a hugely successful Fairtrade producer which supports more than 15,279 cotton-farming families arranged into 13 cooperatives across 400 villages.

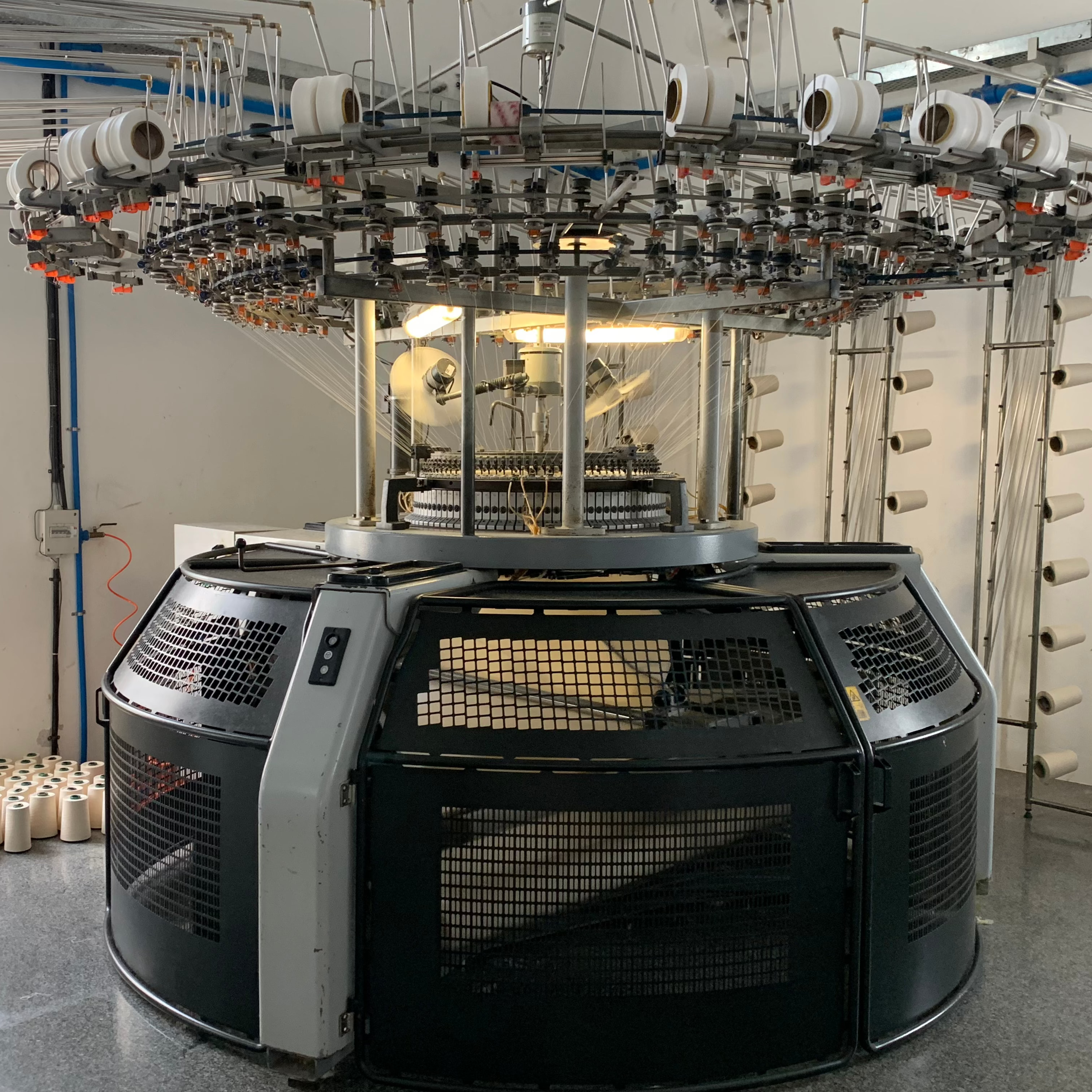

Knitting

The process of all our underwear starts with the knitting of the cotton. This is done in Tiruppur- the knitting capital of India and the city where our main factory is located. The cotton thread are knitted with this massive knitting machine and combined with 5% elastane to give our underwear that comfortable stretch! The rolls of fabric are then sent off to another factory to be dyed and printed.

Printing and dyeing

All our underwear is dyed in another factory in Tiruppur using vast buckets of low-impact dyes. Our patterned materials are more complex and exciting. It is done with this rotary printing machine where it is rolled through various colours and prints in order to create our colourful designs!

Our manufacturers use low-impact, fibre-reactive dyes that are safe and GOTS certified. They contain no heavy metals or other known toxic substances and meet all of the EU criteria for eco-friendly garments.

Cutting and sewing

The next step is the cutting of the dyed and printed fabric. Layers of fabric are laid upon each other, 50 layers thick! The garment workers then use our underwear patterns to cut out the right shapes with a huge cutting machine all ready to be hand-sewn together by the factory's skilled garment workers.

High quality finish

The finishing touches of our underwear is our heat printed labels which are hand done with a heated press before everything is ironed and quality checked. It is then all packed up and sent to us to sell to our lovely customers.

No exploitation in our supply chain

We work with India's leading sustainable and ethical manufacturers. We know that the growers, spinners and makers who produce our underwear are paid and treated fairly. In October 2024, Sarah Jordan, CEO & Founder of Y.O.U underwear travelled to Chennai and Tiruppur in Tamil Nadu, Southern India to visit Connoisseur Fashions and to see first hand how our organic cotton underwear is made. Read her travel blog here.

SA800 Standards

SA8000 certified social standard certifies there is:

- no child labour

- working hour compliance

- minimum wage compliance

- overtime compensation and incentives

- rights of Freedom of Association

- no discrimination for race, age, sex, political opinion or religion.

Additional benefits at Rajlakshmi Cotton Mills include transport to and from the job site, company sponsored meals, a health plan and funding for workers' children's education.